Raising consumer consciousness on how to safeguard electronic devices from voltage fluctuations is a significant factor for the proliferation of the power supply systems in India. This naturally has created a high demand for the transformers used in them. For the transformer industry to thrive, taking into account the demand and supply gap associated with utility power, the rate of industrial growth and the rising level of revenue for consumers, it needs to focus on affordability and innovation.

The function of transformers:

Transformers transfer power from one circuit to another without changing the frequency, thus protecting the secondary circuits and people from electric shocks with the change of voltage and current.

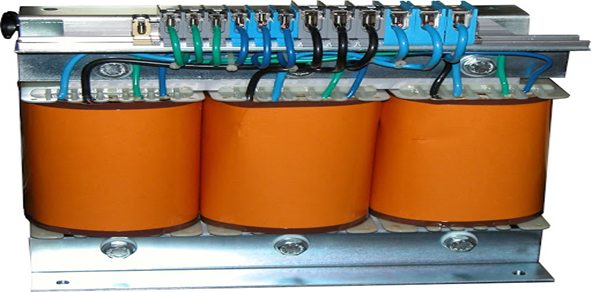

Transformer based technology greater than 100 kVA is suitable for industrial applications manufactured by Distribution Transformer manufacturers. An isolation transformer is used for galvanic insulation, which separates the power output from the input power circuit electrically and physically.

Transformer’s working principle:

The transformer is containing an input connection, an output connection, windings or coils and a core. When the input voltage is applied to the primary winding, the AC flows in the direction of the primary winding and sets the changing magnetic field in the core. When this magnetic field crosses the secondary winding, an alternating voltage is generated on the secondary winding. The ratio between output voltage and input voltage is equal to the ratio of the number of turns between the two windings. There are different configurations for single-phase and three-phase systems. The ratio between the actual turns of the wire in each coil decides the output voltage and hence the type of transformer.

The two types of transformers available in the industry are listed below-

Step-up transformer: The output voltage of this transformer is higher than the input voltage and if the secondary winding changes the wire more than the primary winding, the output voltage will increase.

Step-by-step transformer: In this transformer the secondary winding has lesser turns than the primary winding and the voltage output is lower.

Adherence to the latest technology and quality control measures ensure that it works smoothly. Some of the key features of an efficient transformer are:

- Low noise

b. Compact and lightweight

c. Air flows between the coils and from layer to layer between the coils and the core, so that heat escapes faster and the temperature decreases.

d. Insulation Class H or F.

e. Moisture-proof.

Facts to contemplate before purchasing a transformer:

- Depending on their design, build and installation requirements, transformers come with different capabilities that determine how much power a particular device can handle before overloading. Below are some important parameters to consider when choosing a transformer.

- Voltage required by load: This is the output voltage or secondary voltage of the transformer required to operate the load (lights and other equipment).

- Frequency of supply source: Frequency of supply source and load should be equal.

- Supply voltage: It is essential to find the available power from the utility source or voltage to connect to the primary of the transformer.

- Amperes, kVA or wattage requirement by load: The size of the transformer is determined by the kVA of the load and it is important to add the whole device components. The kVA load must be equal to or greater than the current requirements and account for future expansion. There are different parameters for single-phase or three-phase installation.

Classification of transformers:

A transformer converts electricity from one type to another, with no difference in shape or size. Here are some types of transformers used in power supply systems-

Instrument Transformers: Also known as precision ratio transformers, they are used in conjunction with standard low-range measuring instruments to measure high values of current or voltage produced by Industrial Transformer manufacturers. As the name implies, they are converted in exact proportions to allow the attached device to measure current or voltage without running full power through the device. When the ‘current type’ of an instrument transformer measures the current at AC voltages, the ‘potential type’ measures the voltage at AC.

Isolation Transformers: These types of transformers separate energy sources from powered equipment, thus protecting the equipment and their users. Due to their ability to reduce noise and power, they are ideal for devices that require a high quality power supply for efficient operation. The primary purpose of these transformers is to isolate the circuits against the more normal transformer operation of the voltage converter processed by Control Transformer manufacturers. Power supply systems with such transformers have been found to be sturdier, pliable and have quality frailty management. Therefore, the demand for these transformers in power supply systems is increasing.

Electronic Transformers: These are commonly known as inverter transformer and used for small power converters or to obtain the required voltage. Power transformers commonly found in substations are similar to this variant, but they are used to convert large amounts of power fabricated by Servo Control Voltage Stabilizer manufacturers. All inverter transformers are power transformers but not all power transformers are inverter transformers.

Basis of using isolation transformers:

When operating power supply systems by supplying regular power to the output by input wave model, isolation transformers are used to isolate the bottom load so that the load and the power supply system are completely separated from the bus, even in bypass condition. Here are some ways in which these transformers work.

- Voltage conversion: It can be designed as step-up or step-down – the connected loads receive the voltage required to convert the voltages to the desired level.

- Reduces flaw current supply to loads: These transformers reduce noise and fault current, thereby ensuring proper operation of the connected devices

- Loads require strong grounding: in some cases, the power supply system’s grounding system has a high resistance, but the connected loads require a very strong grounding. In such cases, the isolation transformer ensures safe and proper operation.

- Use on sensitive equipment: Connecting equipment used in the medical field to the isolation transformer before connecting to the power supply system ensures reliable operation and protection from electric shocks.

- Effortless maintenance of power supply systems: This design is easy to maintain as there are isolation transformers in addition to the power supply system, and this design prevents electric shocks during testing or service of the power supply system.

Power supply systems are leading to the growth of transformers due to the recent increase in electricity demand in India due to, urbanization, industrialization and population expressed by Distribution Transformer manufacturers. However, the possible increase will depend on standard, test classification, state-of-the-art technology. Fix up, restoration and maintenance are the subsidiary factors to ensure a fair return on investment.